Jack Haddock worked on the buses at Walsall Corporation from 1941 to 1945, initially as a. Grease Boy and later as an apprentice and fitter in the engine shop. Walsall were big users of Dennis buses and Jack related his experiences during the difficult war years in a series of articles published in the A&D Bus Owners Newsletter. The series has now been gathered together and archived for members of the Dennis Bus Owners Association. The story starts with Jack's introduction to the Bus industry. Future chapters we will relate his experiences with Dennis E Types and the pre-war Lance and Lancet Chapter 1 A dark, gloomy November morning at 7.l5am in 1941 was to me the start of a most interesting and educational time of my life. Having left school in October I was to start work at Walsall Corporation's Depot at Birchills as a. grease lad for a few months, then to be a. fitter's apprentice on the mechanical maintenance of Motor Bus Operations. Due to commence work at 7.30, I was in the clocking-in Time Office at the entrance to the fitting shop. Mr Harold Bayliss was the timekeeper on duty. He was a strict disciplinarian, in the mould of the old Victorian factory martinettes. As ghostly figures appeared in oil smelling overalls to assault the time clock, some wished the timekeeper "good morning", others did not (those who had long standing feuds with the timekeeper). Presently one workman clocked in and stood beside me, wished me good morning and asked if I was his new lad. He confirmed that he was Mr. Harold Heath in charge of No 4 greasing bay with three lads. He proceeded to escort me to number four bay. Upon arriving at the bay, I soon realised it was not a place of any comfort. The bay doors faced the. north west winter wind. Large tanks of oil and grease were adjacent to the pit, plus the many bins of quantities of essential sawdust. The first ritual of the morning was to huddle against the rows of hot water pipes and drape our days supply of cleaning rags on the pipes. If one was lucky the pipes would possibly be lukewarm. Mr Heath introduced me to the other lads and explained the rota of oiling buses. Eight buses comprised a day's work. The garage foreman supplied daily roster for each greasing pit. The problem was, being wartime, every bus available was out on the morning rush-hour traffic. As the morning specials began to return to Birchills depot via Carl Street and passing the rear of Nos 4 and 5 bays, the bus numbers were observed for those on the day's duty rota. As soon as one was sighted Mr Heath would head for the petrol filling bays to receive the bus from its driver after he had filled his fuel tank. On my first morning the bus I saw being driven up the gloom of the bay was Dennis Lance No7. Everyone immediately dived down the pit. I soon found out the reason for this ritual: it was to warm one's hands on the hot exhaust pipe. After a warm, each lad had to perform his required greasing tasks. The basic tasks of topping up engine, gearbox and differential required two lads. One had to operate the handle of a two wheel trolley with 25 gallon oil drum whilst the other lad was responsible for topping up to the required level. Springs had to be cleared of mud and painted with used oil. On a rainy day the bus would be soaked underneath and in snowy weather the thawing slush would often drop down one's neck. In these vile working conditions a grease lad had to await promotion to one of the various maintenance departments. One Monday morning I was told to report to the fitting shop foreman Mr. Frank Somerfield, brother of the General Manager of Walsall Corporation Transport Department. He told me to work with Mr. Frank Clenton, one of his fitters, working bus engine overhauls. Frank was an exceptionally good fitter of the 1920 to 1930 period. He acquired his skill the hard way - by trial and error. Our job was to fully overhaul a bus engine that had been completely worn out. The engine first had to be removed from the chassis, dismantled, cleaned, new main and big end bearings fitted and cylinder blocks re-bored. A bus was often out of service for four weeks or longer. Sometimes buses in service suddenly acquired faults like burnt out valves, big ends running, engine rear oil seals leaking and burnt out clutches. In these instances a fitter and his mate would attend' these faults with the intention of getting the bus back in service as soon as possible. Each fitter had his own part of the shed for his work. Frank Clenton had a corner with bench vises at the top part of the fitting shop, originally the tram fitting shop. Here we completely overhauled our bus engines. Part of our large bench space was occupied by Charlie Ballinger, one of Walsall's first ever bus drivers. Owing to ill health he was given the job of maintenance of bus water pumps. You were lucky if you secured a permanent position in this fitting shop. It was the warmest part of Birchills depot by virtue of being nearest to the Lancashire boiler at the top end of the fitting shop. In any case the doors were kept closed, unlike the motor bus shed with movements every few minutes. For our running repairs we were allocated pit No 1 in one bay of the motor bus shed. We removed engines from bus chassis and wheeled them to the fitting shop on a vintage wooden four wheeled truck, originally designed for the movements of tram electric motors. The routine that I settled into with Frank was to be interesting. In 1942 war conditions were bad. Air raid warnings were a nightly occurrence. Our working hours were from 7.30am to 5.00pm, but we were asked to work until 7.00pm to help keep the bus fleet mobile. On Saturdays we worked from 7.30am to 12.30 or 4.00pm. Sundays were always rest days. We never had to remain permanently on an engine overhaul at our fitting shop bench. A routine fault in pre-war Dennis Lances was the constant battle' of replacing rear flywheel seals. Being poorly designed at the crankcase rear end, the oil seal retaining springs would give way, thus allowing oil to gradually immerse the clutch plate, causing slip. This task was usually completed in two days. In the winter of 1942 Frank Clenton and myself were involved with bus No 189. It was acquired from the Leyland Motor Corporation in 1936 after 12 months service as a demonstrator. Originally fitted with a torque converter, when it was on trial in Walsall, a normal crash box was fitted. During the winter of 1941, 189 was approaching Shelfield from Walsall Wood in icy conditions when, after a skid, it overturned. During the extensive period of body repairs the engine was removed and found' to be in need of a complete overhaul. Being the only Leyland in Walsall's fleet, no spares were in the stores. The engine was taken to a Leyland repair garage situated at Dudley. It took almost 12 months for 189 to receive its new engine. We fitted the new engine and were most impressed with the quality and Precision of the Leyland TDC4 bus.

Most of Walsall Corporation's E Type Buses became surplus to requirements prior to World War Two. The arrival in 1931 and 1938 of Dennis Lancet II coaches with Park. Royal B38F bodies were a vast improvement in design and comfort for drivers and maintenance staff. With the advent of war the few remaining E Types in store became reinstated for emergencies and subsequently were called upon to perform tasks, some being most extraordinary. No. 90, the- tower wagon and No.71, the tow bus retained their original Vickers bodies, but the remainder of E Types performing war service had been rebuilt with new bodies by the Corporation's body shop and a local bodybuilder, W D Smith. To my recollection the numbers were 51, 54, 58, 64, 65, 66, 67, 68, 69 and 72. At the outbreak of the war No.64 was converted into an ambulance. The seats were removed and placed against the windows leaving the centre floor space to accommodate stretchers. Fortunately it was never used, if it had, patients would have suffered much discomfort owing to Type's rigid and hard springing.

By 1944 Walsall had sufficient ambulances so No.64. found its way back into rush hour service. It still retained side seating thus allowing many standing passengers. Most of its sister E Types would beat work assisting morning and evening works services, especially in the Darlaston area that contributed much to the war effort. Some of the E Types were enrolled In a most unusual capacity about the time of the Dunkirk crisis. Just after Dunkirk the possibility of a German invasion of England was a probability. The authorities became aware that a mass invasion by troop carrying gliders could materialise, that the local Aldridge grass airfield would be suitable for this new formed method of aerial invasion. I well remember Billy Hall and Horace Labrum of Birchills Depot staff driving many of the E Types onto the Aldridge airfield to create obstacles for any such aerial invasion. No71, the towing bus came in useful on this occasion by virtue of its towing hook welded to the rear chassis frame. Also to act as a deterrent to foil landing gliders, the authority acquired surplus farming implements, such as old plough shares and farm carts. So No.71 did the necessary work to ensure Aldridge Aerodrome was effective as a deterrent just in case the invasion occurred. This procedure lasted only during the crisis, immediately after Dunkirk and with the advent of winter 1940, Hitler turned to night bombing of Britain's cities. The E Types returned to Birchills Depot to find another duty during the Blitz era from 1940 until almost the end of the war. During the night, Walsall Corporation's fleet which consisted of some 200 buses, were confined to the garage premises. About this time, Coventry had most of its tram and bus fleet destroyed in one heavy air raid. Walsall Corporation and other authorities decided to disperse buses to adjoining side streets within a short distance of the depot. The plan for bus disposal of Walsall Corporation buses was to park about thirty buses that came off duty without defects and to fill with petrol, then depart to their disposal streets. Three chosen streets for disposal of the Corporation's buses all within approximately one mile from the depot were Derby Street, in the North Walsall area, Beeches Road and Somerfield Road in the Leamore area. Each Street accommodated approximately thirty buses. The disposal routine consisted of one Dennis E Type with two shed staff to depart to the appropriate streets to await buses arriving from Birchills Depot after refuelling and cleaning by the shed staff. Each bus then formed a queue behind the E Type. It was the two duty staffs' responsibility to have all bus engines running in time for the drivers' arrival to commence early morning service. In winter conditions a problem arose especially with the Dennis petrol buses minus starters. Thus the attendant E Types were equipped with towing chains. If the temperature became minus zero the staff had the laborious task of draining each radiator, then all had to be refilled in the early hours of the morning (no anti-freeze in those days). The water authorities allowed a standpipe with a tap for this operation. On a cold morning, the task of starting the Dennis petrol buses by hand demanded patience and strength. Any buses not responding to a limited time of cranking gave the shed staff no option but to tow. Thus the procedure was to tow any offending bus around the 2 local streets. Considering that all these buses were within a residential area, the noise from these activities at approximately 4am in the early hours soon brought complaints from local citizens. These complaints were to no avail however. The authorities' answer was "Don't you know there is a war on." The spartan conditions endured by the two shed staff on these street disposal shifts would not be tolerated in these modern times. From 8pm to 6am the only food for the men was sandwiches and a bottle of cold tea, (no thermos flasks available then). As regards heating the solution was to keep the E Type's engine running all night and huddle against its warm radiator. By late 1944, with the war progressing in favour of the allies, this system of bus disposal ceased much to the relief of the disposal men. Another E Type with an interesting role was No.54. By about 1941, increased services to aid the war effort brought about a serious driver shortage. Regular drivers were reporting for war service and men unfit for the armed forces, but otherwise able to perform civilian duties were directed to train as bus drivers. No. 54 at this time assumed duty as an instruction bus. Until after the war, No.54 would be seen about Walsall bus routes on training duties with its resident driving instructor Mr Ike Mew. When taking into consideration the skill demanded to drive a Dennis E type with its lack of self-centering steering, heavy clutch, footbrake and helical gears plus the starting handle being the only means of starting the engine, it must have been quite a task to train a novice driver. Many did however succeed in passing their driving test to become a PSV driver and this included some female drivers. To enable the instructor to have access to his pupils, the window behind the driving seat was removed. Shortly after world war two, No.54 ceased to be used for instruction duties. The bus was retained in stock until about 1950. One of its last duties was as a-mobile polling booth.

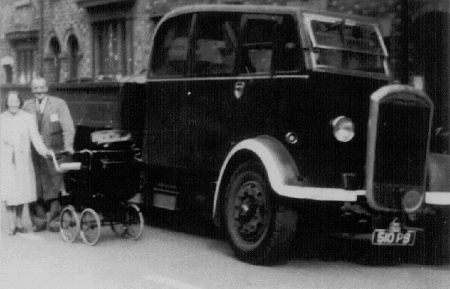

In 1938, E Type No.90 was converted in Walsall Corporation's Birchills depot bodyshop into a tower wagon, to cope with the needs of Walsall's expanding trolleybus fleet. The rear overhang was cut of f and a strong wooden tower erected directly above the rear axle, with a centre screw and winding handle, facilitating a lift of several feet. The front part of the' saloon was retained with seats for the breakdown crew, but the rest of the interior was converted for tool chests and spare parts, to cater for overhead problems. After conversion it must have weighed more than ten tons. A towing hook was also fitted to enable No.90 to tow a disabled Sunbeam six-wheel trolleybus. So this Walsall tower wagon, with its four cylinder petrol engine did, at times, perform yeoman tasks of recovery. No.90 had a resident driver who was responsible for maintenance and cleaning. He always worked early shift and his name was Billy Morris. He had started work as a steam tram driver for the old South Staffordshire Tramway Company and then was a tram driver for Walsall Corporation. He was about to retire in 1939, but with the advent of the war was asked to stay on and did so for the next six years. Billy Morris and No.90 became a legend at Birchills Bus Depot. Bill regarded the tower wagon as his personal property and treated it as if it were his own car. No.90 had its own garage space and at ten minutes to six in the morning, Bill would carry out the daily start up ritual. He would first remove a Corporation issue bus driver's overcoat that had been draped over No.90s radiator by the previous night relief driver. (Bill got very annoyed with anyone failing in this task.) He then took up his stance to engage the starting handle. About 20 turns of the cold engine got the oil to loosen up the engine. Bill then turned on the petrol tap underneath the autovac, gave a few more turns on the starting handle to fill the carburettor. He then climbed into the driving cab to retard the magneto ignition and give full choke. Then he would return to the front of No.90, engage the starting handle and the tower wagon would always start within five snatches of the handle. Once the engine was running it was taken off full choke to be run at a fast tick-over until warm. At no time would Bill leave Birchills depot on a cold engine however great the emergency. Occasionally a Sunbeam MS2 trolleybus would be a total failure and then No.90 would tow the offending bus back to Birchills Depot. An exercise of this nature involved No.90s four cylinder side valve engine moving approximately seventeen tons weight. It was on one of these breakdowns, during a hot summers evening in 1944, that it was realised that No.90 was in need of a new engine. From Wolverhampton No.90 just about managed to climb two hills near Willenhall Cemetry in first gear. After this episode Frank Somerfield, the Birchills shed engineer, ordered a replacement engine to be made from various remaining B type spares available. When the engine was complete, it was decided that No.90 would, on a certain night, have its engine changed after the last service trolleybus at about midnight, in order to be ready for service about 5.30am that morning. To enable a quick engine change, Frank Somerfield engaged three fitters to work non-stop during the early hours to accomplish this vital task. This they did with the encouragement of double time, which was very welcome in those days. When Billy Morris arrived for work at 6.00am No.90 was ready for duty with the engine running at a fast tick over. With the new engine a bit tight to hand crank, on subsequent mornings the night fitters had to start No.90. After all, Bill was almost 70 years old and it took time to loosen up its white metal bearings. It was some time before Bill was able to train the new engine to the starting perfection of its predecessor. In 1946 No.90 was replaced by a second hand AEC Monarch but came in for use on tree cutting on various routes especially in the rural Cannock Chase area. It was finally withdrawn on 13th October 1960. Had it not been for the advent of World War two, Walsall Corporation's Dennis E Type buses would have gone to the scrap heap. However a number survived, carrying out essential work and by about 1942 the survivors began to experience a shortage of spare parts. Very few parts could be obtained from Dennis Brothers Works at Guildford or from the local stores. At the time the pre-war buses were withdrawn, a local scrap dealer from North Walsall, less than half a mile from Birchills Depot, acquired a number of the redundant E Types. This scrap yard was owned by a Mr Harry Glaze, a very shrewd and enterprising local business man. He started this scrap yard in the early 1920's. By 1939 its contents consisted of machinery of all descriptions. To cope with the shortage of E Type spares the Walsall Corporation management approached Mr Harry Glaze to sell back various parts of his E Type collection. He was only too happy to oblige and with his sound business capabilities was now to make a handsome profit on the deal. One of the E Type buses, No.71, on withdrawal from passenger service, was allocated to general duties mainly as a towing bus. When the bus was withdrawn, the saloon was equipped with heavy towing chains and tools. Incorporated in the medley of recovery gear was a solid teak pole some ten foot long and four inches diameter. At each end of this pole was a round leather buffer. Its purpose was to propel dead trolleybuses into the long trolleybus shed or motorbuses into the equally long fitting shop. To do this a man had to walk between the dead bus and No 71 holding the pole against the protruding E Type's chassis and a solid part of the dead bus. When propelling in the trolleybus shed one had to contend with pits along its five roads, thus the pole bearer had to balance his way along the pit's edge. The shed staff at Birchills invariably had problems starting buses in freezing weather conditions. For buses that failed to start by a few turns of the starting handle, the method was to perform a tow start by No 71. After a few hours of constant towing the bus would be resting in the drive between the old tram shed and the motorbus shed. When passing, one would hear crackling noises emitting from the thrashed engine as it contracted. No.71 was also fitted with a snow plough which made the job of swinging its own starting handle a more precarious experience.

Another E Type, No.49 was the subject of an earlier experiment. In 1930, Mr Vane Moreland (then General Manager) authorised the fitting of an experimental Gardner four cylinder L2 diesel engine into this bus. He was well aware of the economics and power regarding development of the diesel engine. To accommodate the slightly larger engine the chassis had to be extended some two feet, with. the radiator protruding forward. Some drivers misjudged the extension when parking. On 19th September 1930, the bus attended a conference for the Municipal Tramways and Transport Association at Harrogate to demonstrate this new mode of omnibus power. By 1931, Gardners had made substantial progress in diesel engine design. They had produced a model expressly for transport work. Gardners offered a new engine (probably a 4LW) and the Transport Committee authorised fitting this new engine rated at 68 bhp. No.49 ran with its second engine until December 1932 when the new General Manager (Mr M J Somerfield) decided it should revert to its Dennis E type petrol engine. Walsall Corporation B Type buses gave good service during the late 1920's and early 1930's, and contributed much to the war effort of 1939-1946. In purchasing these Dennis E Types Walsall Corporation certainly had value for money well spent. Chapter 5 By 1939, Walsall had over 80 Dennis Lance and 42 Lancets in operation, many with petrol engines. To the shed fitters at Birchills depot all the petrol and oil 4-cylinder buses were known as Big-Fours. The drivers- of Walsall Corporation regarded the single deck Dennis coaches as sufficient working with a full load but preferred the petrol versions for keeping time plus speeds approaching 40 mph and smooth running. In the case of the oil engined Dennis coaches they were inclined to be sluggish and would only attain 30 mph, also noise and vibrations made the drivers prefer the petrol versions. Driving the Walsall Corporation double deckers both petrol and oil when under full load, drivers were of the opinion that these Dennis products were grossly under powered. Up to 1937 all the Dennis buses purchased had petrol engines and the next buy was a batch of 12 double deck Lance II 4-cylinder petrol buses numbered from 173 to 184. The last of this order, No 184 was fitted with a Dennis 04 diesel engine. Dennis Brothers conditions were for this bus to be used for evaluation trials, stating the extra cost for the diesel engine would be £140 and if not successful or suitable for Walsall Corporation's needs, they would replace it with their Standard 4 cylinder big four petrol engine free of charge. The period of trial was to be six months. This engine gave satisfactory results and averaged 10.5 miles per gallon against the petrol big four engine's 4.5 miles per gallon. Looking through the Walsall. Corporation Transport Committee minutes for 1940, there is a claim from Dennis Brothers pressing for settlement of this experiment and was ready to accept £110 for the transaction in 1937. The General Manager then settled this outstanding deal. Having worked and driven No 184 during the war years I found it prone to noise and vibration. To compare the Big Four petrol engine and the 04 oil engines in Walsall's Dennis fleet, the petrol engine was the best to maintain and overhaul. Many man hours were consumed scraping and bedding in white metal big end bearings. Dennis Brothers had agreed to fit all Walsall 04 oil engines with phosphor bronze big ends at their own expense and repairs to the crankshafts and phosphor bronze bearing was undertaken by the Harold Andrews grinding firm at Selly Oak, Birmingham. The 4 cylinder blocks of Big Four petrol and 04 oilers were the same bore, but these blocks had an innovation of 1930s design, wet cylinder liners. These liners were in theory, simple to remove, but occasionally some did at times create a problem. The tool to remove these wet liners consisted of a cup to fit the underside of the liner drilled in the centre for approximately a one inch rod. This rod then went through the liner to about nine inches above the block face. Two iron blocks then fitted to the nearest cylinder head studs to support a block of iron with a centre hole to accommodate the centre liner bolt drilled with a BSF threat with a large nut. All one had to do was to apply a spanner of some two feet in length, apply tension and the liner would gently move out of the block. With the engine removed from the chassis the cylinder block would have to be tied to work benches plus several men holding the block. After being made aware of these problems Frank Somerfield, the depot foreman insisted when liners were to be removed the the-cylinder block was left in the bus chassis, minus sump, big ends, pistons and cylinder head. Then remove the liners when the block was secure. Even so, occasionally a liner would refuse to move after full tension on the spanner plus extension tubes. Then the fitting shop blacksmith's striker would be employed to assist with an underarm blow to the bottom of the liner cup with an extension bar held by a man with callipers. Arthur Sambrook, the blacksmith's striker, did not take kindly to this inverted method of his routine practice. One day a cylinder defied all these methods-of removal. So Frank Somerfield, after much thought and deliberation, decided to apply the cylinder block onto a redundant hydraulic press still intact in Birchills depot fitting shop previously in use to press on and off tramcar tyres. Frank Somerfield hastily erected a barricade of bus panels around the press and cylinder block then ordered workmen to a safe distance in case the block split under extreme pressure. A sudden bang announced the wet liner moving to the relief of the fitting staff concerned with this exercise. Fitting new liners to the Big Four and 04 cylinder blocks was comparatively easy providing one fitted the rubber seal situated at the base of the block. Another problem with the Dennis 04 engine was a tappet noise, with each cylinder operating two inlet and two exhaust valves. Also the rear main crankshaft bearing, when worn, put pressure on the seal thus resulting in oil being deposited on the clutch plate. Nevertheless these Dennis double deck Big Fours and 04 oilers gave useful service during the early World War II years. In 1942, eight Dennis buses were destroyed by enemy action. This included Big Four petrol double deckers No.179 and 180 plus 04 double deckers Nos. 192, 195 and 205. The buses were completely burnt out by incendiary bombs. In 1942 some buses were destroyed by enemy action, completely burnt out by incendiary bombs. With the war effort in full swing the spare part situation for buses was indeed critical. Subsequently, some buses remained out of use for some time, awaiting engine parts. They were cannibalised to such an extent that only the chassis and bodywork remained intact. Two of the Dennis Lance "0" buses built in 1935 were, in late 1942, towed away to Dennis Brothers works to be completely overhauled and fitted with Dennis Lance 4 oil engines. These two were Nos 106 and 111. Dennis Lance II overhead valve petrol buses Nos 118, 123 and 173 were out of service from 1941 until 1943 along with Lancet II coaches Nos. 135, 139 and 172. Evidently priority for spare parts was eventually granted and these buses returned to service. All shock absorbers had been removed owing to lack of spare parts. It is safe to say that these Dennis shock absorbers were never efficient at the best of times. Front broken springs occurred at regular intervals, resulting in a constant hammering of the chassis with the swing of the shackle. This sometimes broke the chassis. It was commonplace for buses to be overloaded especially during the blackout. (It has been known for certain conductors to fill the lower deck to a point that no one could move.) Still, there was a war on and workers had to be transported. In the case of a broken chassis, a fitter and his mate removed the bus engine to enable the shed welder to strengthen the chassis. The welder, Bert Thompson, performed miracles fitting 3/8" steel plate into the broken chassis, joining the rear front spring anchor bracket that was riveted to the downward sweep of the chassis towards the low section holding the passenger compartment. A favourite spot for welding a chassis was the top of No 1 road of the trolleybus shed. For the fitters mate a filthy task was to clean all the layers of oil and grease from the section to be welded. The layers of grease were often an inch thick. To scrape this off, sawdust was spread below in the pit. Even when cleaned up there was always a problem that, during welding, sparks might start a fire. Subsequently, Bert always had a mate handy with a fire extinguisher. On the next pit, top of 2 road, was the section reserved for relining and maintaining of trolleybus brakes. For washing oil stained brake linings and hubs, petrol in buckets was used freely - some yards adjacent to this chassis welding! These conditions, welding amongst oil, petrol, grease and sawdust would not be tolerated today, with factory health and safety rules, but in 1942 this was the case at Birchills Bus Depot. By the end of the war every Dennis bus of the mentioned series had strengthening plates fitted on both chassis, some two feet either side of the spring anchor shackle bracket. Just after America joined World War II the petrol supply was American petrol, and was of a much higher octane than our previous supply. At first, this higher grade petrol was very much appreciated by the bus drivers, who found greater pulling power and acceleration to Walsall's Dennis petrol buses, although some drivers found this out to their cost, when swinging the starting handle. In the case of uneven ignition settings, the resulting kickback was a trip to hospital to treat a broken arm. Approximately two or three months after the introduction of this new grade a calamity occurred. Arthur Westley, the running repairs and ignition fitter, received reports concerning bad pulling of almost every petrol bus. It did not take long to diagnose lack of cylinder compression due to burnt out exhaust valves. Almost two thirds of the petrol buses had two or three valves in a very bad state of wear, some almost split in half by the heat generated by the high octane cylinder explosion. Strangely enough, the Dennis Lance II buses fitted with side valves were not affected for some time - these were buses numbered 101 -106, 110 - 117 but the Lance II buses, double deckers and single deckers fitted with the later improved overhead valve engine, were subject to a high rate of valve failure. I well remember the task of grinding in new valves by hand. Sometimes each fitter and mate had two buses to work on at the same time. Once I ground in a set of new exhaust valves for bus No 120 and within a month they had burnt out again. Also, the valve seatings began to feel the effects of lead petrol. This entailed the sending away of the cylinder heads for reseating to a well known firm at Selly Oak, Birmingham, Harold Andrews Ltd., who also had the contract' for cylinder relining and boring, and crankshaft regrinding for Walsall Corporation. I used to detest the cleaning of ; carbon from the valve ports. With a sharp knife one could scrape off carbon with ease, but in the case of this American high octane petrol the port cavities had a deposit of white carbon almost like cement and one literally had to chisel it off. It was almost six months afterwards that, after many complaints, the Ministry of Supply arranged for a new supply lower octane petrol. Looking back, now, on those days I suppose Walsall and other municipal bus services were lucky to have petrol, considering the high loss of tankers crossing the Atlantic, not to say the many brave seamen who gave their lives to enable Walsall to have a wartime bus service.

Walsall Corporation would not have had so many of the Guy utility buses but for another calamity that interfered with Walsall's attempts to keep the wartime bus service running. Just prior to Christmas 1943 the tide of war was beginning to turn in our favour and the Birchills Depot staff was allowed two days holiday. The weather on Christmas Eve was sunny and mild as the staff retired home. During the night, however, the wind turned east and the temperature fell rapidly. A sharp frost greeted daylight on Christmas Day with all the best buses, including the new Guys, inside the depot. The street disposal buses were brought in to be parked on a field to the rear of the Birchills Depot. On Christmas Night and in the early hours of Boxing Day the temperature dropped even lower. These buses were first visited by the shed staff at about 4 am to be started up for the first workers specials. A surprise greeted them for some thirty buses were found to have cracked cylinder blocks, not to mention burst radiators. As no spare engines or cylinder blocks were available, due to wartime conditions, a system of improvisation was thought out by Frank Somerfield, the mechanical foreman. He immediately ordered a supply of 1/8" brass plate with 3/16" taps and screws. Then it was the soul destroying task for fitters and mates to drill around each cylinder block crack (some extended about one foot). Then came the laborious ritual of drilling and then tapping with' three taps from fine to coarse through the brittle cast Iron blocks. To save time the bus engine was not removed and this job had to be done lying across the front nearside mudguard. Occasionally, a steel tap broke off inside the cast block which then had to be drilled out with difficulty and an oversize tap then used. This task was eventually achieved' with the aid of a lot of language not found in the standard Oxford Dictionary. Most fitters and mates worked 7.30 am till 7 pm in the effort to get buses on the road. After a few weeks these buses were back in service but used only on morning and evening specials. Despite the cylinder block patching, external leaks continued. A new substance called "Holts Wonder Weld" was on the market about this time. It was decided to try this gritty compound which was supposed to flow through the offending leak thus congealing and stopping the flow. This it did but it also managed to block radiator tubes and hoses with bus radiators boiling over at regular intervals. Such was the state of Walsall's buses during this mid-war period, that at all bus terminals on the Corporation routes a watering can had to be available to deal with offending radiators. One day during 1944, another fitter, Frank Clenton, and I had a pleasant interruption from our engine repair routine. The Walsall fleet included two Dennis Lance 6's, Nos. 215 and 220, which were the latest Dennis products to challenge the dominance of Leyland and AEC in the public transport market. They were an improvement on the previous Dennis stock at Birchills Depot, but because they were new at the outbreak of World War II, they did not go into full production at Dennis Brothers until after the war. These two Dennis Lance 6's were originally demonstrators and, during the war, Dennis Brothers' engineers, despite turning their Guildford Works over to military vehicle production, still found time to check the reliability of buses 215 and 220. These buses were fitted with the then new Dennis O6 diesel engine. These became very popular with traffic staff and proved very reliable. No major faults occurred and they had a fuel consumption of six to eight miles to the gallon, in contrast to their Dennis O4 counterparts average of four miles to the gallon. Frank and myself had the task of removing the rear axles and engines of these two buses for examination at Dennis Brothers' Works. The two buses had been in service at Walsall from 1939 and 1940 and after inspection by Dennis Brothers at Guildford the engines and axles were returned completely overhauled. I believe the axle incorporated the differential Sun and Planet gears operating in both wheel hubs. After removing the components from the two buses, the stores lorry arrived from Dennis Brothers with spares for Walsall Corporation's Dennis Fleet. The lorry conveyed spare parts to all private operators and municipalities that purchased products and was of an unusual design. It was a lorry constructed on a Dennis Lance chassis incorporating a sleeping cabin for two men. The crew consisted of a driver and fitter plus all tools required for maintaining Dennis vehicles. We were informed that this lorry could be used for experiment and testing of various engine modifications.

On the day of its arrival we met the driver of this unusual lorry. He explained to us the lorry was in fact a Dennis 06 chassis fitted with the same 100bhp power unit and axles as our two 06 buses. What impressed Frank Clenton and myself was that this experimental lorry was fitted with a sleeping compartment for the driver. We loaded the Dennis lorry with our 06 parts with the assistance of the fitting shop overhead manually operated crane. Some weeks later the parts returned and when on test with buses 215 and 220 we came to the conclusion that Dennis had at last a very efficient and powerful bus to compete with its rival manufacturers. One of the Dennis E types, No 71, was converted into a breakdown and towing bus, when withdrawn from regular bus duties in 1937. It was new in 1928, but during its life as a towing bus from 1937 until it was scrapped in December 1944, it took a fearful hammering of rough usage, being called upon to tow buses out of ditches, crashes and snowplough duties. All shed lads during the war years were taught to drive this No 71 from the age of fourteen to help the elderly fitters and shed staff. With the young men in the forces, a lot of shed maintenance staff consisted of ex-bus drivers taken off the road with stomach trouble and arthritis. Consequently, these semi-invalids were only too glad for eager, keen, young lads to do their driving. The number of tasks that were required of us by the fitters were many and varied. Two daily visits to the canteen were allowed during the morning and afternoon tea breaks. Each lad was required to serve the artisan staff near his pit area or workbench. This usually entailed carrying about a dozen pint tea cans plus a number of cakes, if available. The entrance to Birchills depot was always a scene of activity. We fitter's apprentices only ventured into this area to deliver repaired ticket boxes to the cash office. About twenty girls worked in this office, under the strict jurisdiction of a stern spinster, name of Miss Casement, who strictly forbade any skylarking with the girls. The ticket boxes were repaired in a small space in the fitting shop by a Charlie Ballinger. He worked on the next bench to Frank Clenton and myself and one of my tasks was to keep Charlie well supplied with snuff. Although Frank and I were more or less totally involved in engine repairs we were often involved in mishaps to Fitting Shop machinery or bus smashes and road breakdowns. Normally for these happenings Birchills Depot had the services of two very practical handymen. Their main task was to maintain the trolleybus overhead wires, but any tasks that required attending to that called for emergency skill (such as a bus overturning or buried in Cannock Chase snowdrifts) these two men, with their immense strength and total lack of fear, would be called upon to do the job. This pair always worked together as a team and could indeed be classed as characters. Their names were Albert Harkhall (the brains) and his partner Albert Mason (the faithful assistant) who were better known at Birchills Bus Depot as "Gog' and "Magog". I remember one Herculean task they were called upon to perform in 1943 when trolleybus No 159 was struck by lightning near Willenhall Board Schools. The crash had ripped the steering column and front axle from the chassis, rendering steering impossible. This pair managed to secure the axle back to the chassis by means of strong rope to hold it in position - the bolt holes and spring shackles were all torn to shreds with the impact. No towing ambulances were available in those days for heavy vehicles. The means of steering was to have an extension lever bolted by a plate to the drag link drop arm. With Mason walking beside the trolleybus he steered the bus all the way from Willenhall walking alongside at a slow pace, pulled by the towing wagon engaged in bottom gear. Whilst repairing the various engine components at our fitting shop bench I was involved with some interesting workers who formed the backbone of Birchills Bus maintenance routine. It was always a full time job repairing bus radiators. A certain Arthur Bickley waged a constant battle with the Dennis radiators. They were of poor design, and it was safe to say that a Dennis bus in wartime conditions with a radiator that did not leak was a rarity. The AEC radiators were of a better design and gave very little trouble. This fitting shop possessed a blacksmith and striker who were a very efficient pair. They were true craftsmen and never failed to make a job of the varied tasks allocated to them. Jack Woolf was the blacksmith and Arthur Sambrook his striker, and during the period I was at Birchills Depot from 1941 to 1945, they never had adays absence from work. Next to the blacksmiths hearth were three lathes, very ably worked by a Mr Walter Rose. Opposite the lathes was the bench of another engine fitter, Len Lowe and his mate Sid Turner, and they used the pits originally designed for tram repairs. Nearby was the bench of Gilbert Powell and his mate George Bently. Both these fitters were allocated complete engine overhauls and often their buses were out of service for months. The days of replacement engines at Birchills depot were yet to arrive. As if anyone about this time - in 1943 - at Birchills needed a reminder that there was a war on, it was an announcement one day to clear number 5 bay of buses. Within days the Royal Air Force took over the bay. It was to be used for the storage of aircraft engines, such was the production rate of factories engaged in the war effort. One day curiosity got the better of some of us lads which resulted in us approaching the Royal Air Force guards to see one of the stored engines. At a suitable moment we were allowed into this highly guarded bay. Stacked approximately twenty feet high were hundreds of gigantic packing cases. A sergeant produced a crowbar to prise the lid off one for our benefit and to this day I shall never forget the sight of a Rolls Royce Merlin engine in its full glory. "It's either for a Spitfire or Lancaster" he informed us, and when we asked for one to fit to one of our Dennis Lance buses he was highly amused at the thought of this combination. In Birchills depot, five pits comprised the "1" bay maintenance section, all linked by one wide main pit complete with benches and heavy screw jacks for lowering gearboxes and axles. No 1 pit was allocated to Frank Clenton and myself and was very awkward to drive a bus onto, owing to the close proximity of the bay door. No 2 pit was used solely for brake repairs and adjustments. The brake fitter was Joe Blackwell, a very good-living person with strong religious feelings - he was always trying to curb us lads of using foul language. He could not drive and all brake road testing was done by his mate. No 3 and 4 pits were used for gearbox and differential repairs. In charge was Billy Holmes and a mate who overhauled all transmissions, including clutches. No 5 pit was a spare and was often used for fitting the odd big end failure. Another pit was situated top left of "1" bay. This was used for semi-engine repairs like fitting big ends and new pistons, and valve grinding. Arthur Hinton and Ray Nightingale always worked on this pit. Top right of "1" bay was a small extension shed with a steel roof, a tiled floor and glass windows. This was the diesel injector calibration and fuel pump maintenance room. Cleanliness was the order of the day, away from the sawdust and grit that prevailed in "1" bay. George Collier and Billy Hall worked full time in this department. At a bench in No 2 bay 3 Arthur Westley waged a constant battle with carburettors, autovacs, magnetos and coil ignition problems. The rest of the services essential to bus maintenance were contained in the fitting shop, next to the old tram shed. In the fitting shop was, starting from the Bloxwich Road end, a large electric motor, driving a shaft of some thirty yards. From belts along this shaft, power was provided to work three lathes, a large press (originally designed for pressing on tram tyres and used later for pressing liners out of wet cylinder blocks). Two large drilling machines also used the same power source and also a blower for creating a draught for the blacksmith's furnace. The noise in this lower section of the fitting shop was intense, mainly due to the overhead shafting that operated all the fitting shop machinery. Next to the fitting shop was the five road trolley bus shed and I, along with other lads, had to journey twice a day across the shed entrance to get tea from the depot canteen. The sight of trolleybuses reversing from the shed and turning in a tight circle on the small cobblestone apron was always interesting, as during the war years most of the buses had a conductress. The lads were always willing to help change the trolley poles for the girls. This tight circle played havoc with Walsall Corporation's Sunbeam M52 twin rear axle trolleybuses. The strain on the oil seals during turning was responsible for subsequent oil leaks on the rear axle's brake drums. At the top of number two road a brake fitter waged a constant battle with oil soaked brake linings. The welders bench was for some unknown reason situated in the paint shop of all places. Whilst welding was in process, dust and matter would be floating about in the vicinity of buses being painted and varnished! Situated next to the paint shop was the body repair shop. Us lads of the fitting shop did not assist the carpenters - they had their own assistants, but we paid regular visits to the body shop to sweep up vast accumulations of sawdust. This we used in large quantities by depositing it on the pit floors, some inches deep to absorb surplus oil. After a few days or between bus repairs we had to sweep out the pit, burning the oil soaked sawdust in the field adjacent to the sheds. On my daily travels through Birchills Depot with its shed artisan staff, numbering some 200 workers, I came into contact with some other characters. One was always bumping into a very friendly man named Freddie Whittle. Fred was a man of immense girth and must have weighed about twenty stone. Originally he was a tram and bus conductor but had to relinquish the job owing to being unable to mount the staircase and gangways for his size. The only task he could undertake was to clean oil from leaking half shaft seals. You would see him walking from the bus carrying a bucket of paraffin, a brush and a small stool to sit down on whilst cleaning the hubs. The small stool was made for Fred by the Depot carpenters and written on the side was "load not to exceed 2 tons". A set of men that did a very efficient job on Walsall's buses were the night cleaning men. All the years I worked at Birchills Depot I only saw them on Friday mornings at pay time between the hours of 11 am and 12. These nocturnal workers came on duty at 10 pm to 6 am. All buses were washed down and cleaned by hand with brushes, mops and cold water. Each bus went out on the morning service immaculately clean and smelling of fresh disinfectant. Even though a war was on, Walsall's buses were always reasonably clean, even in bad weather. In 1943 it was decided to experiment with gas producer buses. At first approximately twenty 2 wheel trailers complete with coke fire and container to collect heated gas were delivered. All these trailers were stored in the paint shop whilst outside in the permanent way yard a large supply of special anthracite coke accumulated. One of the AEC Regent petrol buses was taken out of service for conversion to producer gas. The bus was No 38 and the engine was completely overhauled with special emphasis on enlarging the cylinder bore and fitting of special pistons. The fitter to undertake the conversion was Dick Taylor, who for a short period was sent to the Birmingham Corporation Bus Depot at Perry Barr for instruction on the methods of gas producer bus operation. They had a number of their AEC petrol buses operating on the City to Perry Common route. After a lot of hard work and endeavour bus No 38 was put in service on the Brownhills route to assess the capabilities of the wartime method of fuel economy. One obstacle was the approach to Walsall Wood canal bridge from Walsall. This was the bridge before the present day bridge. It was very narrow, hump backed and steep. With a full load the gas bus could just crawl up the slope engaged in bottom gear. No 42 was converted along with No 38 but both gas producer buses were not a success owing to the problem of hills on all Walsall Corporation's routes. I believe they ran reasonably successfully in other parts of the country on routes where no hill climbing was involved. After about six months Walsall's gas producer buses were converted back to petrol. Whilst running on gas they often had to switch back over to petrol when in trouble. In any case in 1944 new Guy utility buses were arriving in large numbers and these two AEC buses were withdrawn from service along with the other AECs. By virtue of their reconditioned engines they were purchased by the coach firm of Yeomans of Canon Pyon near Hereford for transporting RAF personnel between Hereford and the Gredenhill RAF Training Camp. Perhaps the most vivid experience of my time at Birchills Depot was one evening in 1942. Before clocking off at 7.30 pm we moved bus No 113 from No 1 bay pit, after fitting a new engine, into the driveway between the motor bus shed and the fitting shop. The following day we were to run the engine in, at a fast ticking over speed, then to give 113 bus a test run in the afternoon. A sister bus, 117 was put onto our pit for the next engine overhaul. During the night Birchills Bus Depot was the victim of an incendiary bomb air raid that occurred at approximately 4 am. I was at home in the garden shelter at the time and remarked to my father about heavy rain falling. It did not take long for him to say "keep in the shelter" for the sound was of incendiary bombs hitting the ground. Well over a thousand bombs fell in a small area just off the Bloxwich Road and in no time the sky was ablaze. Hawleys Tent Works was the first to set fire. No 2 bay of Birchills depot was soon ablaze, trapping a number of buses. It appears that the raiders were returning from a raid on Liverpool but had some incendiaries left over. They probably sighted Talbot Steads and the Birchills Bus Sheds and assumed that they were above Birmingham. Many bombs failed to explode and the Fire Service put these temporarily in the permanent way yard. I estimated there were about two hundred of these. The worst damage was to No 2 bay, with three quarters of its length destroyed. From this blazing bay one of the Birchills Home Guard, a bus driver named Corporal Kitson, drove many buses from this burning bay, some on fire. For his exploits he was subsequently awarded a medal. Only a few yards away in the adjacent petrol shed was stored many thousands of gallons of petrol that fortunately did not explode. Despite the air raid and damage about 75 per cent of the required bus services ran, priority given to essential works services. The sight that greeted me as I reported for work that morning was the remains of burnt out buses still smouldering with only the warped chassis to remind you of a bus. The buses were Nos 87, 192, 195, 205, 179, 180 and 113. I found my way through the debris to 1 bay pit, after finding the bus 113 we were due to test completely destroyed. Bus 117 on our pit had a hole in the roof and midway between the top deck seats was an incendiary bomb, covered with a sandbag. Frank and myself decided to keep well clear. Only three days after the fire, as I turned into the depot yard to clock on, I saw a line of six Manchester Corporation double decker Crossleys sent down to help our depleted fleet. The following day four London Transport AEC Regents with open rear staircases arrived. Later two Bournemouth trolleybuses arrived to assist, although no trolleys were put out of action. The six Manchester Crossley Condors were numbered 208, 252, 271, 272, 275 and 288. The London Regents were numbered ST842, ST844, ST847 and ST1017. Bournemouth trolleys were numbered 78 and 79. Frank Clenton and myself found ourselves and other fitters trying to keep the Manchester buses on the road. They had been stored awaiting scrapping and were in bad condition. Timing chains were always running dry, due to blocked lubrication pipes. It was very rare for all six of the Condors to be in service at once. The London and Bournemouth buses gave almost no trouble. The incendiary bomb raid took place in July 1942, 1 believe, and despite the buses acquired from Manchester and London it was only with great difficulty that Sid Haynes could produce enough buses each morning to keep the service intact. The Corporation had negotiations with the Ministry of Supply, knowing that the Government allowed the construction of utility buses to replace bus losses from enemy action nationwide. One dark gloomy November morning in 1942 after clocking on, word got around that two new buses were in No 3 bay. Curiosity prevailed amongst us lads to see these new arrivals. The elder fitters and shed staff remained at their benches and pits knowing full well they would see enough of these buses in the future. These first two new buses were Guy Arab Mark 1 types, painted in Battleship Grey and fitted with wooden seats similar to park benches. They were soon driven to the paint shop to have the numbers 192 and 195 allotted after the Dennis Lance types which were lost in the blitz. It took about two days to register these buses and fit destination rolls. At regular intervals afterwards more followed to finally total seventy six by the end of 1945. As more new Guy Arab buses arrived the clapped out Dennis buses began to be phased out of service, much to the delight of the fitters. To go back to the bus engine repairs with Frank Clenton, we had to gradually acquaint ourselves with the Gardner 5LW engine as fitted to the growing fleet of Guy Arabs. It was decided to maintain these new buses according to the maker's instructions with regular top overhauls and periodic maintenance. We soon found out that, at long last, Walsall Corporation had bought a more reliable bus, as opposed to the somewhat inferior design of the pre-war Dennis products. One feature of these utility wartime Guys was that their Gardner engine parts were made of cast iron instead of aluminium. It surprised Frank and myself, as we lowered the first sump on bus 222. The weight took us by surprise after being used to lighter Dennis ones. It was 'fortunate the front axle was available to rest it on. The gearboxes were also cast iron and, owing to some design to enable oil seals to perform efficiently, heavy duty oil was added to the gearbox. Whilst running hot these Guy gearboxes were easy to change gear, but on cold mornings it called for the utmost strength to engage first or reverse gear to move out of the garage. Gear sticks were known to be bent performing the operation. An unusual task for two Walsall Corporation Dennis E Type buses occurred in August 1944. World War Two was beginning to proceed in favour' of the allies. The local council decided to allow a certain amount of relaxation mainly to give local war-workers a break from many hours hard work during the first dark days of the war. It was decided to run a point to point horse race meeting on the August Bank Holiday Monday. A local farmer gave permission to use his land on the Walsall to Aldridge Road opposite the Dilke Arms public house. With no accommodation for a jockey's weighing room and a bookmaker's office, Walsall Corporation was approached to loan two buses for this purpose. They duly obliged by supplying two of their ageing Dennis E Type buses. The Birchills shed staff modified the buses interior by removing some seats and fitting tables. Shedmen Horace Labrum and Billy Hall had the task of delivering the two E Types for this one off occasion. In later years they were of the opinion that Walsall Corporation Dennis E Type buses certainly gave value for money in the various tasks performed in addition to their normal earning service revenue. During the summer of 1945 many of us lads had to report to the Wednesbury Road Labour Exchange to register for the Armed Forces. Derek Cowley, Ray Dolman and Alfie Ward had already been called up. Sid Turner,: George Bentley, Dennis Craddock, Sammy Salt, Gordon Hatherway and myself were all called up too. The weeks before most of us received our calling up papers most of our veteran Dennis Lance and AEC Regent buses were scrapped, thus leaving the mainstay of Walsall Corporation's fleet relying on the new Guy utilities and making maintenance a lot easier for fitters. So in late 1945 I left the Birchills Bus Depot for service in the Royal Air Force, with my previous mentioned mates serving in all three services. Some returned after their service but I did not. Looking back with hindsight, it was a privilege to work at Birchills during the war years. It was a most precarious existence and it was a miracle that England survived. The friendship of the characters and staff of Birchills Depot has never been equalled since. Walsall Memories - by Jack Haddock

|